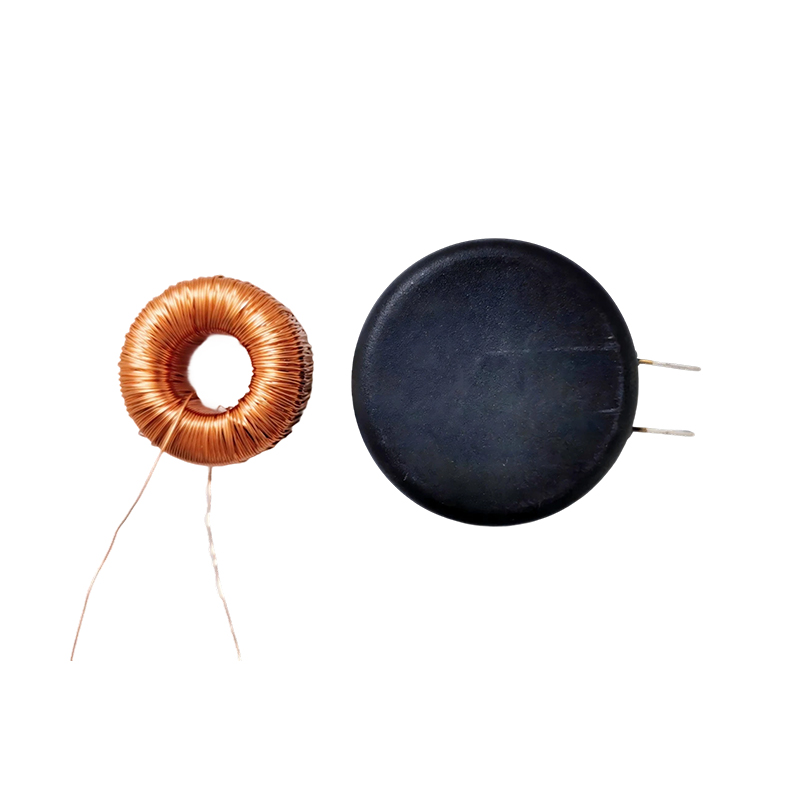

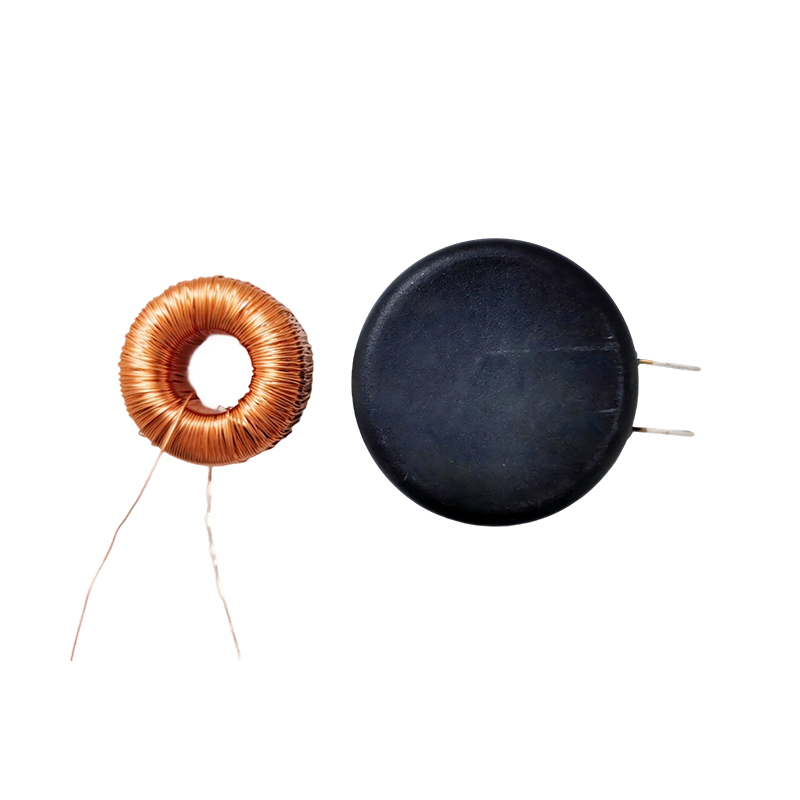

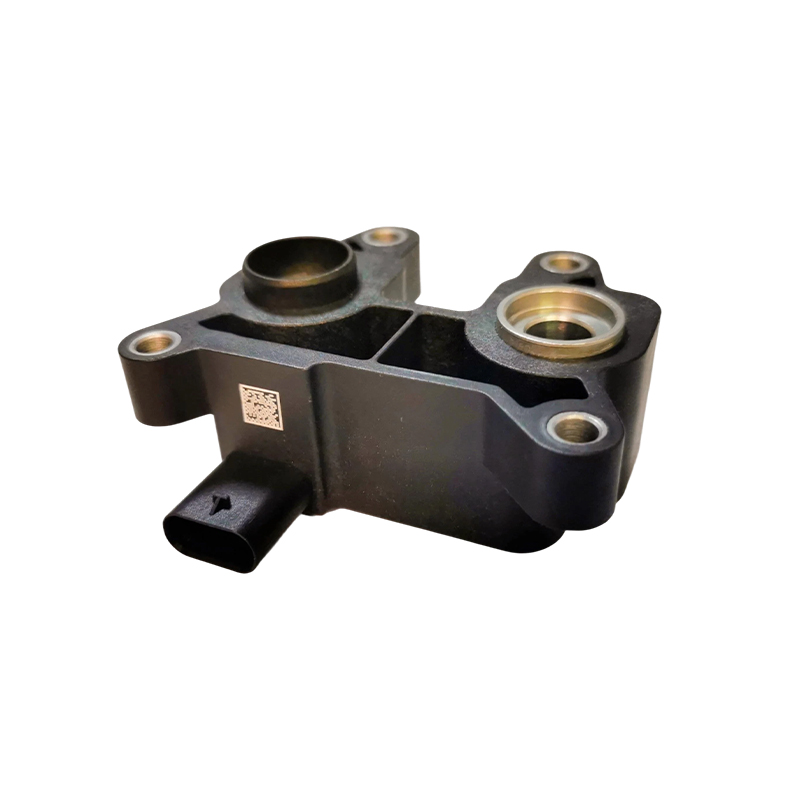

Testing the inter-turn insulation performance of the vehicle airflow solenoid valve coil is a crucial step in ensuring the reliable operation of the solenoid valve.

- +86-13967899365

- venusco.xu@venusco.cn

- Building A, No. 18 Keyuan North Road, Ninghai County, Ningbo City, Zhejiang Province