Copyright © Ningbo Venusco Electronic Technology Co., Ltd. All Rights Reserved. Site Map

- +86-13967899365

- venusco.xu@venusco.cn

- Building A, No. 18 Keyuan North Road, Ninghai County, Ningbo City, Zhejiang Province

I. Project Basis

1. Current Status, Level and Development Trend at Home and Abroad

The vehicle-mounted air flow control solenoid valve coil is a key component in the automobile engine management system, and plays an important role in the normal operation and performance optimization of the engine.

Its functions are mainly manifested in:

Accurately control the intake volume: Accurately adjust the amount of air entering the engine according to the engine's operating conditions (such as idling, acceleration, deceleration, etc.). When the engine is idling, the solenoid valve will appropriately reduce the air flow to maintain a stable idling operation, and during the acceleration process, increase the air flow to ensure that the engine has enough oxygen to mix with the fuel, achieve full combustion, and improve the engine's power output.

Optimize fuel economy: Cooperate with the engine's fuel injection system to keep the air and fuel in a suitable ratio (air-fuel ratio) at all times. A suitable air-fuel ratio helps the fuel to burn fully, reduce fuel waste, reduce the content of harmful substances in exhaust emissions, improve fuel economy, and meet environmental protection and energy-saving requirements.

Improve engine stability: It can quickly respond to changes in engine operating conditions, adjust air flow in time, avoid insufficient or excessive air intake in the engine, thereby ensuring that the engine can operate stably under various operating conditions and reducing engine vibration and abnormal noise. If the solenoid valve coil fails, the engine air intake may be out of control. Too much air intake may make the engine mixture too lean, resulting in reduced power, weak acceleration, and even backfire. Too little air intake will make the mixture too rich, resulting in increased fuel consumption, black smoke from exhaust gas, and the engine may vibrate, idle speed is unstable, and other problems may affect the engine's starting performance in severe cases.

At present, the automotive industry has achieved certain results in the research and development and application of air flow control technology. Major automobile manufacturers and parts suppliers continue to invest resources to improve product performance and control technology. With the widespread application of advanced electronic control units (ECUs) and sensor technology, vehicle-mounted air flow solenoid valve coil control technology is developing in the direction of intelligence and precision.

Therefore, the company plans to develop a vehicle-mounted air flow control solenoid valve coil. Through technological innovation and R&D breakthroughs, the company will improve the performance of the product, achieve precise control of air flow, enhance its stability and reliability, and provide more solid technical support for the rapid development of the automotive industry.

2. Purpose and significance of project development

(1) Through the research of this project, gradually narrow the gap with the international cutting-edge natural gas vehicle-mounted air flow control solenoid valve coil products, improve the cost performance of products, and enhance the company's competitiveness.

(2) Establish project planning, workload allocation, resource balance, feedback on problems during plan execution, solution formulation process, and quality status management model to promote the company's scientific and technological R&D efficiency, solve the problem of disconnection between scientific research and production, promote the industrialization of scientific and technological achievements, support the development of the company and drive the progress of the industry.

3. Technical level and market prospects achieved by this project

The vehicle-mounted air flow control solenoid valve coil control technology of this project has high flow regulation accuracy and fast response speed. It can maintain stable operation under high temperature, high humidity, strong electromagnetic interference and other environments. The overall technology has reached the advanced level of the industry.

The global automobile market is huge and still growing steadily, especially in emerging market countries such as China and India. With economic development and improved living standards, automobile consumption demand is strong. Whether it is traditional fuel vehicles or new energy vehicles (some hybrid models still need this component), air flow control solenoid valves are needed to accurately manage the engine intake volume to ensure the performance and efficiency of the engine. Therefore, the increase in automobile production directly drives the market demand for this product.

II. Development content and objectives

1. Main content, objectives and key technologies of the project

The research and development of vehicle-mounted air flow solenoid valve coils in this project aims to design and manufacture high-performance products that meet the strict requirements of the automobile engine intake system. . Then realize the efficient and accurate control of the automobile air path system and promote the technological upgrading and development of the automobile industry.

Key technologies:

Electromagnetic design and optimization

Electromagnetic principle research and modeling: Using electromagnetic theory, the working principle of the solenoid valve coil is deeply studied. By establishing an electromagnetic model, the magnetic field distribution and electromagnetic force characteristics of the coil under different structural parameters and current conditions are simulated to provide a theoretical basis for subsequent design optimization.

Coil structure design: Determine the key structural parameters such as the number of turns, wire diameter, winding method (such as single-layer winding, multi-layer winding, spiral winding, etc.) of the coil, and the core material and shape. These parameters directly affect the performance indicators of the coil, such as inductance, resistance, and electromagnetic conversion efficiency. It is necessary to determine the best solution through repeated experiments and optimization.

Electromagnetic performance optimization: Use computer-aided design (CAD) and finite element analysis (FEA) software to simulate and optimize the electromagnetic performance of the coil. By adjusting the structural parameters and material properties, the electromagnetic conversion efficiency of the coil is improved, energy loss is reduced, and sufficient and stable electromagnetic force can be generated under given current conditions to achieve precise control of the valve core.

Manufacturing process development

Winding process optimization: Develop high-precision winding processes to ensure that the number of coil turns is accurate, the winding is uniform and tight, and problems such as inter-turn short circuit and wire breakage are avoided. Use advanced winding equipment and automatic control systems to improve winding efficiency and quality stability. At the same time, study how to properly control the tension of the wire during the winding process to ensure the consistency of the shape and performance of the coil.

Assembly and welding process: Design a reasonable assembly process to ensure the precise assembly of the coil and other components (such as valve core, housing, etc.). Develop a reliable welding process to ensure that the electrical connection between the coil pin and the circuit board or connecting wire is firm and reliable, and prevent problems such as cold solder joints and desoldering. Strictly control and optimize parameters such as temperature, time, and welding materials during the welding process.

Packaging and protection process: Develop effective packaging and protection processes to protect the coil from external environmental factors such as moisture, dust, vibration, and chemical corrosion.

2. Technological innovation

(1) Optimize the coil winding process: Use advanced winding equipment and processes, such as tight winding and layered winding, to improve the inductance value and magnetic field uniformity of the coil. Reasonable design of the number of turns can reduce energy consumption while meeting the magnetic field strength required for the solenoid valve to work. In addition, precise control of the winding tension and spacing can help reduce the parasitic capacitance and resistance inside the coil and improve the speed and efficiency of electromagnetic conversion.

(2) Insulation treatment process: Through special impregnation, potting and other processes, the insulating material is evenly filled in the gaps and holes of the coil to form a reliable insulation layer. This can not only improve the insulation performance of the coil, but also enhance its mechanical stability and prevent insulation damage caused by vibration and impact.

(3) Flow characteristic matching: The structural design, valve core shape and size of the solenoid valve are optimized to ensure that the appropriate air flow can be provided under various working conditions to meet the combustion requirements of the engine, improve fuel economy and reduce exhaust emissions.

(4) Vibration and impact resistance design: By adopting measures such as reinforced structural design, elastic support elements and buffer materials, the impact of vibration and impact on the coil can be effectively reduced, and the loose wires and solder joints inside the coil can be prevented from falling off, ensuring long-term stable operation in a complex vibration environment.

3. Main technical indicators:

(1) Resistance: 10.3Ω±0.5Ω

(2) Number of turns: 750±20 turns

(3) Withstand voltage: 1000V/1S-Max0.5mA

(4) Insulation: DC500V>500MΩ

(5) Salt spray test: No white rust on external metal parts for 240H, no red rust for 720H

(6) Cleanliness test: Maximum metal particles ≤300um, maximum non-metallic particles ≤500um

III. Development test methods and technical routes (process routes)

1. Company's new product development process management

(1) Establish a project team: Establish a project team with Shao Dengwei as the project leader.

(2) Carry out structural design and simulation of the product, and calculate the number of turns and wire diameter of the coil.

(3) Determine the product manufacturing process and mold making, and purchase product trial materials and standard parts.

(4) Arrange relevant processing equipment and parts testing according to the trial production schedule.

(5) Product assembly and trial production verification.

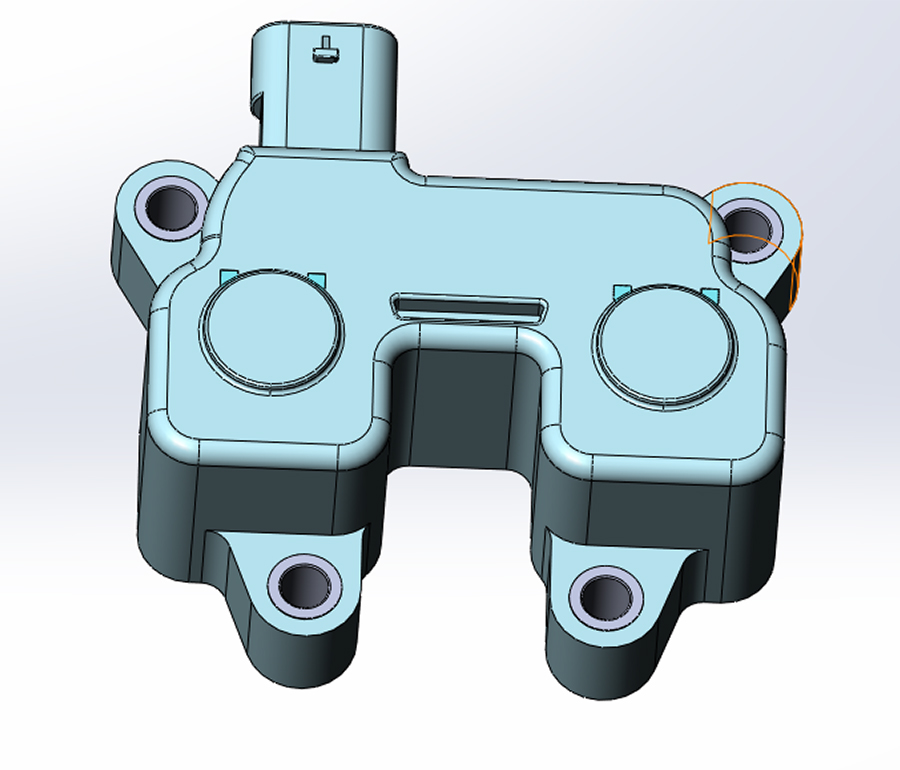

2. The 3D design drawing of the project product is as follows:

IV. Existing development conditions and work basis

1. Advantages of the undertaking unit in carrying out this project (talents, facilities and conditions).

Ningbo Venasco Electronic Technology Co., Ltd., established in 2021, is located in Building A, No. 1088, Xuemian North Road, Taoyuan Street, Ninghai County, Ningbo City, Zhejiang Province. It is an enterprise mainly engaged in technology promotion and application services. The company mainly engages in the research and development and design of electromagnetic coil products. Its core products include electronic components, electromagnetic coils, solenoid valves, and mold manufacturing and processing. It can efficiently and accurately complete the production and manufacturing of various products. It is equipped with a multifunctional and intelligent equipment inspection system, which can conduct all-round and strict inspection of products to ensure that product quality meets high standards. Since its establishment, the company has devoted itself to the automatic control valve industry and has established close cooperative relations with many domestic manufacturers. With thoughtful service, reliable quality, reasonable price and fast delivery, the company provides customers with technical consultation, design solutions, and supporting products, and has established good long-term cooperative relations.

The company has 16 employees, including 4 professional technical R&D personnel, 1 management personnel, and 9 production personnel, and has a complete set of CAD/CAM/CAE design and development systems. The company implements the general manager responsibility system, and has a company office, R&D department, processing workshop, warehouse, etc. The responsibilities of each department are clear, and they work together to form a good working atmosphere. The company pays attention to talent training. It not only has well-trained employees, but also has cultivated an excellent design and manufacturing team. It has mastered the domestic advanced design and manufacturing standards and experience of inductor coils. At the same time, it has introduced world-leading technologies and products from Germany, Japan and other countries. By absorbing, learning from and improving the manufacturing technology of products, it has formed high-end products with independent core.

2. Existing work foundation, such as pre-test and small test results, etc.

The company has invested a lot of money to set up an enterprise design center, purchased advanced processing, testing and testing equipment, and adopted a computer design system to simulate working conditions to ensure the accuracy, reliability and efficiency of the design plan. It can tailor products for special working conditions to better meet customer needs. The company's technical personnel have extremely rich design and manufacturing experience, which can provide strong technical support for the smooth development of this project and provide opportunities for the company's sustainable and rapid development.

May 1, 2024 - May 30, 2024 Complete product trial production, testing, trial evaluation, improve defective designs, and achieve project targets. June 1, 2024 - June 30, 2024 Improve technical standards, obtain satisfaction feedback through customer use, continuously improve technical design solutions, apply for relevant technical patents, and start mass production.