Copyright © Ningbo Venusco Electronic Technology Co., Ltd. All Rights Reserved. Site Map

- +86-13967899365

- venusco.xu@venusco.cn

- Building A, No. 18 Keyuan North Road, Ninghai County, Ningbo City, Zhejiang Province

I. Project Basis

1. Current Status, Level and Development Trend at Home and Abroad

Since the beginning of the 21st century, my country's national economy has continued to maintain a rapid growth trend. my country joined the WTO, and the global manufacturing center began to shift to China. my country's automobile industry is gradually integrating into the world's automobile manufacturing system and has entered a golden period of development. The rapidly growing domestic market and low production costs have attracted global automobile industry resources to gather in China. In 2009, China officially became the world's largest automobile producer and seller.

With the rapid development of my country's automobile industry, automobile electronic control systems and electromagnetic coils have also maintained the same rapid development momentum in recent years. Among them, ABS electromagnetic coils have developed rapidly. Automobile ABS can be said to be one of the three most important inventions in the history of automobile safety. Before the emergence of automobile anti-lock braking systems, automobiles used open-loop braking systems. Its characteristics are that the size of the brake torque is only related to the driver's operating force, the distribution and adjustment of the braking force, and the size and form of the brake. Since there is no feedback information on the wheel movement state, it is impossible to measure the speed and locking of the wheel during the braking process, and the car cannot adjust the size of the wheel lever or air chamber brake pressure accordingly. Therefore, in the case of emergency braking, the wheels will inevitably lock and slide on the ground, resulting in frequent traffic accidents. The emergence of the automobile anti-lock braking system (ABS) fundamentally solves the problem of wheel locking during the braking process. Its basic function is to sense the motion state of the wheel at every moment through sensors and adjust the braking torque accordingly according to its motion state. It is one of the most effective application projects of electronic control technology in automobiles.

2. Purpose and significance of project development

(1) Through the research of this project, effectively narrow the gap with international cutting-edge solenoid valve products, improve the cost performance of products, and enhance the competitiveness of enterprises.

(2) Establish project planning, workload allocation, resource balance, feedback on problems during plan execution, solution formulation process, and quality status management model to promote the management efficiency of enterprises, solve the problem of disconnection between scientific research and production, promote the industrialization of scientific and technological achievements, support the development of enterprises and drive the progress of the industry.

3. Technical level and market prospects achieved by this project

The electromagnetic coil of this project is one of the most indispensable components of the electromagnetic induction system in the automobile ABS braking system. Electromagnetic braking technology has further solved many problems in ABS, such as it is difficult to accurately measure the speed of the vehicle body and wheels, and it is difficult to achieve precise control of braking force. These drawbacks make it difficult for cars equipped with ABS to meet the braking requirements more accurately under ideal road conditions, but it is difficult to meet the requirements on muddy mountain roads with poor road conditions. At this time, the car urgently needs another set of auxiliary braking system to ensure the driving safety of the vehicle. Electromagnetic braking technology has quickly established its position in the automotive auxiliary braking system with its characteristics of no wear, rapid response, smooth braking and good compatibility with the ABS system. It is expected that in the next 5-10 years, with the development of automotive industry technology, the application prospects of automotive electromagnetic coils will be unlimited.

II. Development content and goals

1. Main content, goals and key technologies of the project

In long-distance freight trucks and large buses, diesel brake valves ensure that vehicles can brake safely and reliably under different road conditions such as highways and ordinary roads. Whether it is emergency braking under full load or regular braking in frequent start-stop urban traffic, diesel brake valves play a key role in ensuring driving safety.

Key technologies:

(1) Accurate magnetic field modeling and optimization: Use professional electromagnetic simulation software to accurately simulate the magnetic field distribution of the brake control valve coil. Consider factors such as the number of turns, wire diameter, winding method, and core material properties of the coil to build an accurate magnetic field model. Through multiple iterations of optimizing design parameters, the magnetic field distribution is made more uniform and concentrated on the valve core to generate sufficient and stable electromagnetic force to ensure that the brake control valve can respond to the control signal quickly and accurately.

(2) Low-power electromagnetic design: Under the premise of ensuring the electromagnetic force required for the normal operation of the brake control valve, the resistance, inductance and magnetic circuit structure of the coil are optimized to reduce unnecessary energy loss. For example, high-conductivity wire materials are used to reduce resistance, and the core shape and material are optimized to increase magnetic permeability, thereby reducing the excitation current and achieving energy saving.

(3) Precision winding process: Adopt advanced tension control technology to accurately control the tension of the wire during the winding process to avoid inconsistent tightness between turns and prevent the occurrence of inter-turn short circuit problems.

(4) Fine assembly process: Precision molds and positioning fixtures are used to ensure the relative position of each component is accurate and avoid uneven magnetic field distribution or electromagnetic force loss due to assembly deviation.

(5) Sealing and protection process: In order to protect the coil from dust, water vapor, oil pollution, vibration, impact and other harsh environmental factors, reliable sealing and protection processes are adopted. The coil is potted and high-performance potting glue is used to fill the gap between the coil and the shell to form a sealed protective layer to prevent moisture and dust from entering the coil.

2. Technical innovation

(1) Diesel vehicles have a long service life and usually have more mileage than ordinary passenger cars. We have ensured that the performance of the coil remains stable and reliable under long-term and frequent power-on and power-off cycles in terms of material selection, manufacturing process optimization, and heat dissipation design.

(2) Due to the high working pressure of the diesel vehicle braking system, in order to achieve braking effect in a short time, the brake valve needs to have a large fluid flow capacity. The optimized mechanism design is adopted to allow more brake fluid to flow quickly to meet the pressure buildup and transmission requirements during braking.

3. Main technical indicators:

(1) Resistance: 36.3Ω± 1.5Ω

(2) Number of turns: 1275±1 turn.

(3) Withstand voltage: 500V/1S-Max 1mA.

(4) Insulation: DC500V>500MΩ

(5) Stud torque: Torque ≥2.5N

III. Development test methods and technical routes (process routes)

1. Company's new product development process management

(1) Establish a project team: Establish a project team with Shi Qiang technician as the project leader.

(2) Carry out structural design and simulation of the product, and calculate the number of turns and wire diameter of the coil.

(3) Determine the product manufacturing process and mold making, and purchase product trial materials and standard parts.

(4) Arrange relevant processing equipment and parts testing according to the trial production schedule.

(5) Product assembly, trial production and verification.

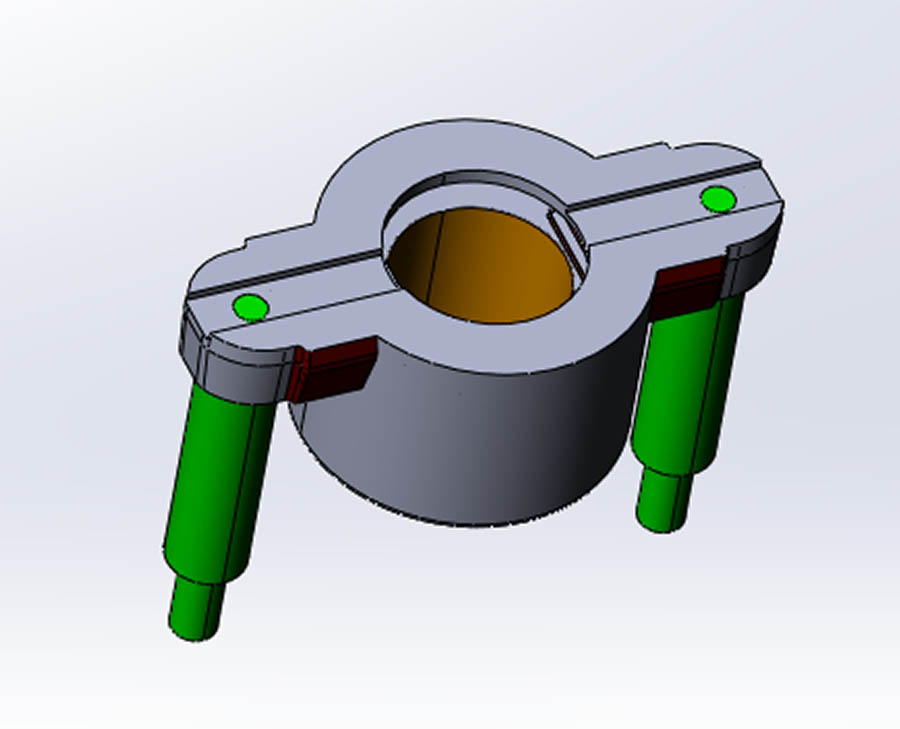

2. The 3D simulation diagram of the project product is as follows:

IV. Existing development conditions and work basis

1. Advantages of the undertaking unit in carrying out this project (talent, facilities and conditions).

Ningbo Venasco Electronic Technology Co., Ltd., established in 2021, is located in Building A, No. 1088, Xuemian North Road, Taoyuan Street, Ninghai County, Ningbo City, Zhejiang Province. It is an enterprise mainly engaged in science and technology promotion and application services. The company is mainly engaged in the research and development and design of electromagnetic coil products. Its core products include electronic components, electromagnetic coils, solenoid valves, and mold manufacturing and processing. It can efficiently and accurately complete the production and manufacturing of various products. It is equipped with a multi-functional and intelligent equipment inspection system, which can conduct all-round and strict inspection of products to ensure that product quality meets high standards. Since its establishment, the company has devoted itself to the automatic control valve industry and has established close cooperative relations with many domestic manufacturers. With its considerate service, reliable quality, reasonable price and fast delivery advantages, it provides customers with technical consultation, design solutions, and supporting products, and has established a good long-term cooperative relationship.

The company has 16 employees, including 4 professional technical R&D personnel, 1 management personnel, and 9 production personnel, and has a complete set of CAD/CAM/CAE design and development systems. The company implements the general manager responsibility system, and has a company office, R&D department, processing workshop, warehouse, etc. The responsibilities of each department are clear, and they work together to form a good working atmosphere. The company pays attention to talent training. It not only has well-trained employees, but also has cultivated an excellent design and manufacturing team. It has mastered the domestic advanced design and manufacturing standards and experience of inductor coils. At the same time, it has introduced world-leading technologies and products from Germany, Japan and other countries. By absorbing, learning from, and improving the manufacturing technology of products, it has formed high-end products with independent cores.

2. Existing work foundation, such as pre-test and small test results, etc.

The company has invested a lot of money to set up an enterprise design center, purchased advanced processing, testing and testing equipment, and adopted a computer design system to simulate working conditions to ensure the accuracy, reliability and efficiency of the design plan. It can tailor products for special working conditions to better meet customer needs. The company's technical personnel have extremely rich experience in equipment and manufacturing, which can provide strong technical support for the smooth development of this project and create opportunities for the company's sustainable and rapid development.